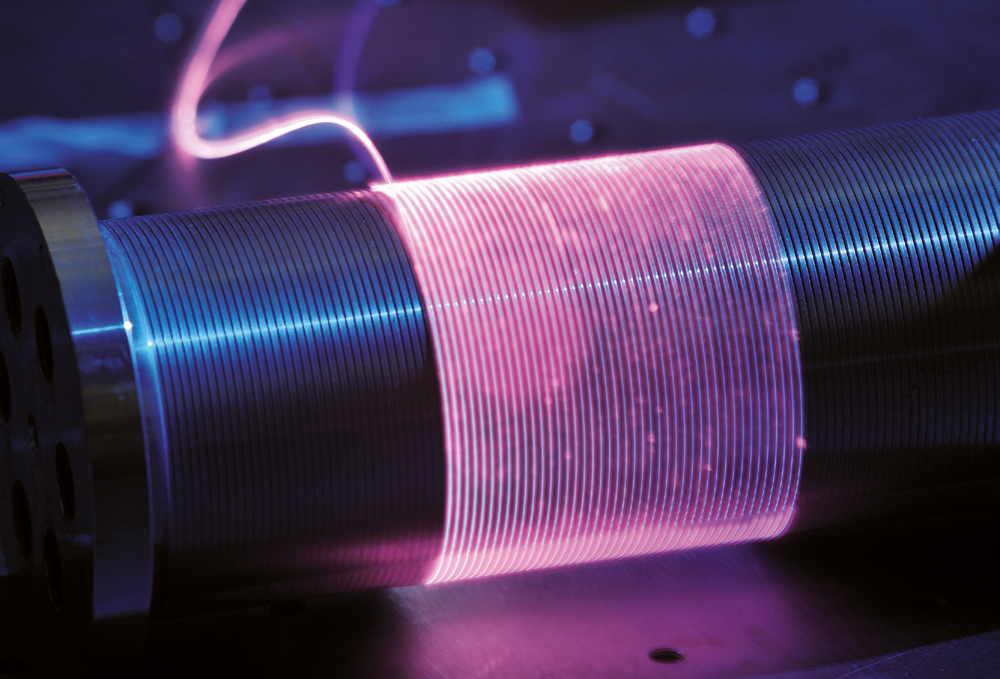

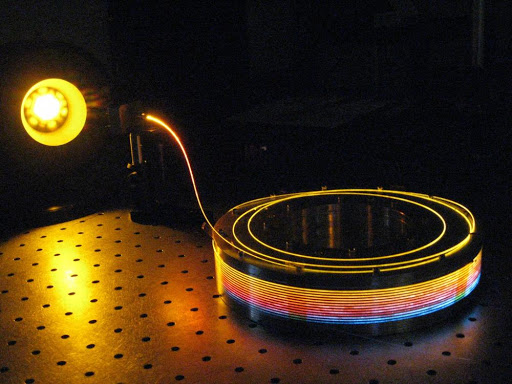

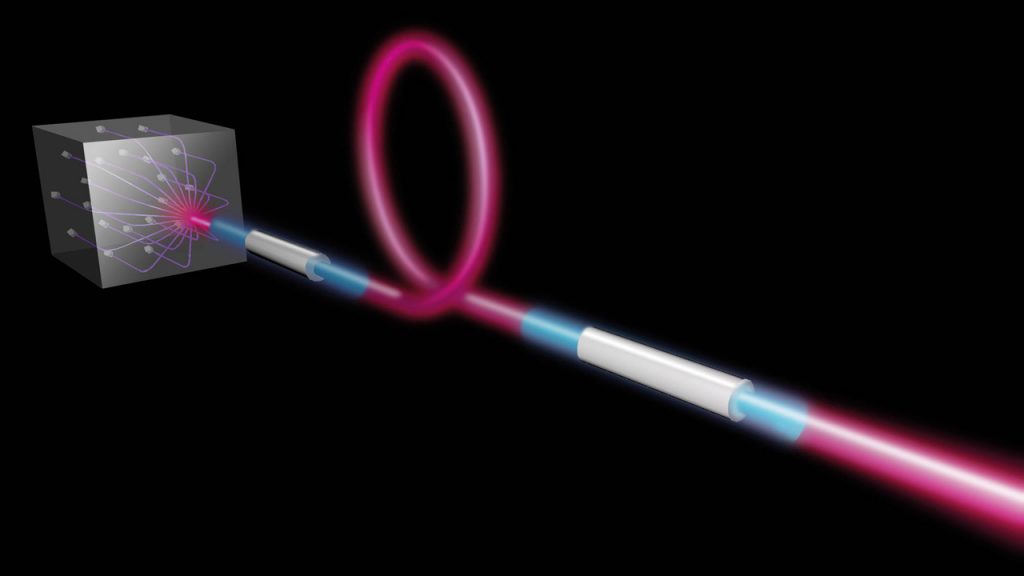

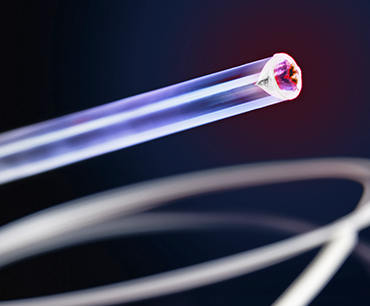

Because of their structures, fiber lasers have several advantageous properties. Due to the large absorption length, surpassingly good efficiency of pumping is possible: generally the wall plug efficiency is around 30-40% (this value is usually less than 1% in gas and solid lasers). A high gain factor can easily be realized because of the large gain length. Due to the small cross section and large surface area, the thermal effects are usually not significant. Fiber lasers have outstanding beam quality because of the waveguide, which is a result of their structures. Beam propagation in the air can be partially or fully eliminated, which significantly increases the stability of fiber lasers and makes them less sensitive to influences of the environment. However the small cross section limits the increase of output power and pulse energy, which is a challenge in the application of fiber optics. Developers have to face undesirable nonlinear effects that are produced by long fiber length in low intensities as well.

Why fiber lasers?

Fiber lasers aren’t the only type of laser on the market, there are insulator lasers, semiconductor lasers, gas lasers and dye lasers as well. Gas lasers, most often the ones using carbon dioxide or helium-neon as their medium, are actually the most common.

All laser processes has advantages and disadvantages as well, but experiences show that the benefits of fiber lasers far outweigh that of the other solutions. Really significant developments of fiber lasers have taken place over the last few decades. Thanks to these developments and the benefits (see later) they have spread around the world fast. Fiber lasers are used in dozens of industries among others in communication, data transfer, medical care and material processing.

Versatility is probably one of the most important benefit of a fiber laser. What makes them so attractive is the fact that they can be applied so easily and seamlessly in different industries and the list of their uses is getting longer. From the marking of plastics and the welding of metals to the perfection of diamonds and medical surgeries, the use of fiber lasers truly makes them the most indispensable and most extensive equipment on the market.

Advantages of fiber laser

- simple, compact

- large surface of the active medium for simple thermal management by air or industrial water cooling

- excellent beam quality

- high electrical and optical efficiency

- high peak energy in pulsed mode

- the laser light is already coupled into a fiber, which eases beam delivery

- reliable even at high output power

- maintenance free (the entire optical fiber can be set up without lenses, mirrors dependably)

| Fiber lasers | YAG lasers | CO2 lasers | |

| beam quality | Excellent | Fair | Good |

| Footprint | Excellent | Poor | Poor |

| Electrical efficiency | Good | Fair | Poor |

| Reliability | Excellent | Poor | Poor |

| Maintenance | Excellent | Poor | Poor |

Full control

The huge range of adjustable parameters offered to the user is what makes fiber lasers easy to apply. This huge parameter range allows you to perfectly adapt the laser beam to the application in which you are working. Although much of the control is the responsibility of the user, the fiber lasers are still easy to operate.

You only need one setup for multiple functions

The same control of the different output options and functions of the fiber lasers means that a fiber laser is suitable for several processes. The multitude of processes, such as laser drilling and laser marking, as well as laser cutting and laser engraving, bear many similarities, making it easy for such a machine to switch seamlessly between different functions.

Working with different materials

Another huge advantage of fiber lasers is their ability to work with a wide variety of materials. With metals, ceramics, silicon, plastics, polymers, precious stones and even precious metals. They are great to apply with reflective metals that other types of lasers struggle with.

Compact size

In general, we can find that fiber lasers are smaller and more compact than many of their other counterparts, making it easier to install in machines and making them lighter as well. This means they are easy to transport and more economical in terms of space and storage.

Low sensitivity

The structure and internal design of the fiber laser are such that its sensitivity to external influences is low. Other types of lasers can be extremely sensitive and can fall out of the setting completely due to a small mechanical impact, making them unusable until they are repaired by a specialist.

Working in a rough environment

Fiber lasers work great in harsh and unfriendly environments. This allows for diverse use anywhere in the world.

Excellent performance

Fiber lasers provide excellent performance compared to many of their other counterparts, as well as a much better quality light beam that is extremely precise to focus on and allows for an increase in energy density. This also means that exercises can be completed faster and with lower energy consumption.

Lower heat output

Fiber lasers are built with more modern cooling systems than previous lasers. As a result, their operating temperature is also significantly lower. This minimizes the heat from the fiber lasers and thus the chance of damage to the machine, as well as increasing its life time.

| Fiber lasers | Nd:YAG laser | |

| Type | solid state | solid state |

| Active material | Yb-doped optical fiber | Nd: YAG crystal |

| Laser wavelength | 1062 nm | 1064 nm |

| Mode | pulsed, cw | pulsed, cw |

| Operating temperature | 0 °C – 45 °C | 10 °C – 40 °C |

| Pumping | diode laser (@ 977 nm) | diode laser (@ 808 nm) |

| Lifetime | >50.000 hours | ~12.000 hours |

| Wall-plug efficiency | ~ 35-40% | ~10% |